Ocean is a force of immense creative power.

For us, it is a true collaborator and a living source of materials and meaning.

A social innovation model

Crafting textiles from marine biomass

Our long-term vision is to promote responsible sourcing practices within aquaculture, ensuring that this industry protects the ocean while sharing its benefits with local communities. Value creation has to go hand in hand with local stewardship and sustainable livelihoods.

Rising ocean temperatures and acidity are increasing both algal invasions and aquaculture waste, with small coastal communities particularly affected. Seafood farmers face waste levels exceeding 50% of production.

At the same time, seaweed communities are projected to lose up to 71% of their distribution by 2.100 due to climate change and pollution. Our work helps these ecosystems to thrive, while enabling the production of high-quality textiles for an industry in urgent need of transformation.

❋ Low material footprint❋ Not water-intensive ❋ Plastic-free❋ Not land-intensive❋ Minimizing reliance on finite resources❋ Not energy-intensiveDriving change in a

synthetic-dominated industry

As of 2023, the global textile market remains heavily dependent on synthetic fibers (polyester, polyamide, acrylics, elastane), which account for approx. 68% of total fiber production. This dominance is largely driven by polyester, which alone represents about 57% of global production. In contrast, fibers derived from aquaculture or alternative sources still account for a negligible share of the market. However, this landscape is expected to evolve: production of natural and more sustainable fibers is projected to grow at double-digit rates by 2033, signaling a gradual but meaningful shift toward a more diversified and sustainable fiber mix.

Alternative yarns made from natural and sustainable fibers, like ours, are projected to grow at a CAGR ~30% higher than traditional yarns by 2033.

Petri dishes with a selection of our raw materials. Clockwise from the left: 1. Light brown invasive algae powder from Portugal; 2. Off-white marine biomass powder (confidential composition); 3. Dark brown invasive algae powder from Mekong Delta; 4. White algae bio-polymer powder.

Blue Carbon

Beyond being low-emission by design, we contribute to the development of the blue carbon potential of marine ecosystems, a critical lever for climate change mitigation.

55-95% less emissions than traditional textiles (% depending on selected blend).

1M+ kg of CO2eq avoided represents the projected positive net climate impact of ER Ocean Recherche project over the next 5 years.

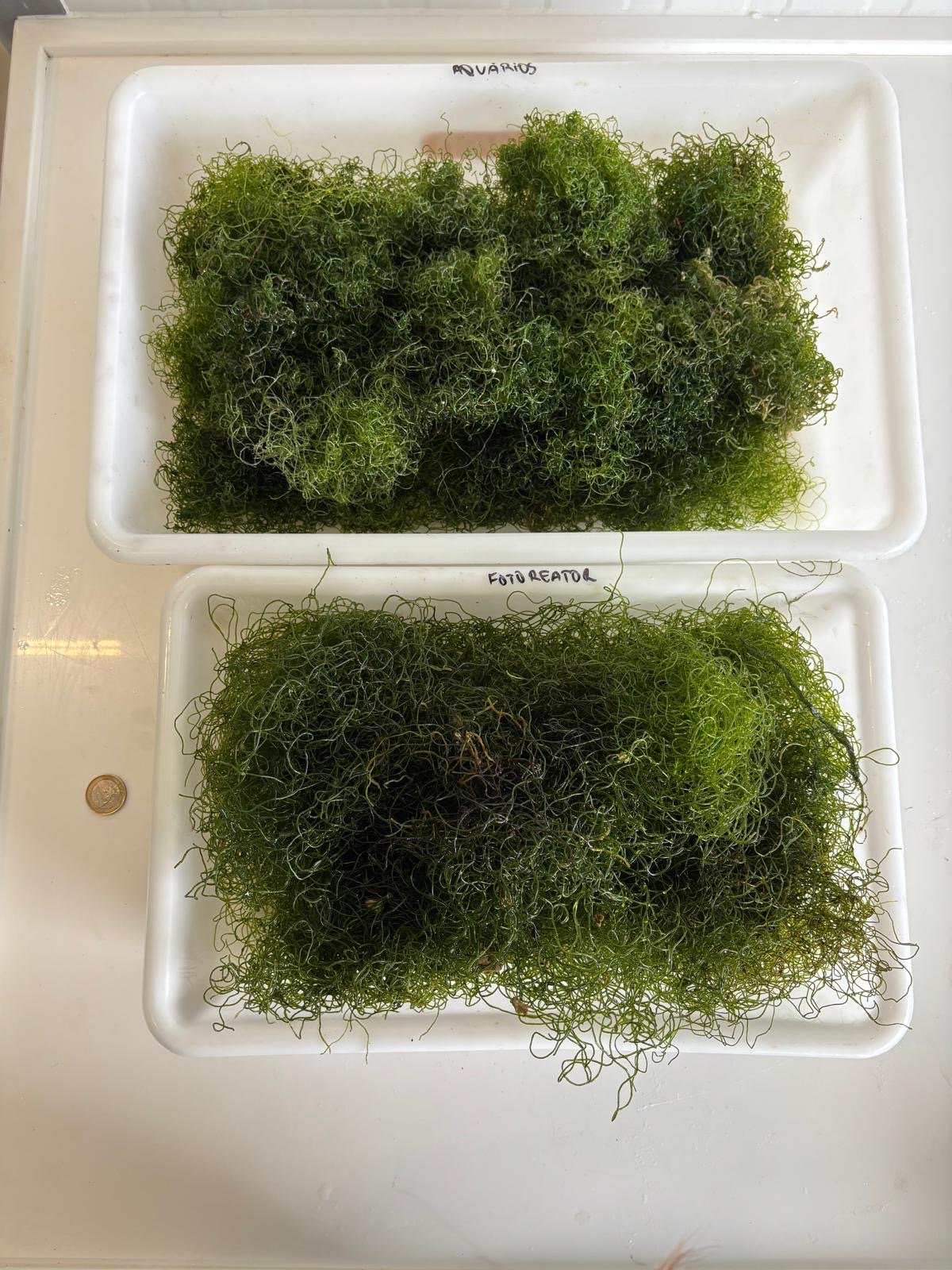

Ongoing study, cultivation of algal biomass, Portugal. This algae strain has been selected for its specific composition, and it contains the key components required to produce high-quality textiles.

Not water-intensive

Most of the marine biomass we use comes either from seawater-based aquaculture or from invasive species collected along the coast, both of which require no freshwater irrigation; therefore our materials need dramatically less water to produce—much less than bio-based alternatives made from plant fibers cultivated in soil.

90% drop in water usage shown by our preliminary life-cycle assessments.

Not land-intensive

By using marine biomass, we have no dependence on wood or intensive forestry. Our textiles do not take up agricultural land or forest resources for cultivation, offering a scalable, land-free solution that avoids land-use competition, while actively contributing to regenerative material cycles.

Low material footprint

Decreasing reliance on virgin resources through the valorization of discarded biomass, including invasive algae. A step towards a more circular economy.

20 tons/day of marine biomass collected by our partner in Nouvelle-Aquitaine, France

Plastic-free

Our textiles do not contain any petro-sourced components. By avoiding conventional plastics and synthetic fibers derived from fossil resources, we develop materials that are fully bio-based.

Nouvelle-Aquitaine, France.